CPV maker Semprius to launch first production facility in North Carolina

Semprius, Inc., a concentrating photovoltaic (CPV) producer said yesterday that it would locate it’s first production facility in Henderson, N.C. The company plans to start producing its lower-cost CPV devices at the facility by August 2012.

Semprius, Inc., a concentrating photovoltaic (CPV) producer said yesterday that it would locate it’s first production facility in Henderson, N.C. The company plans to start producing its lower-cost CPV devices at the facility by August 2012.

At first, the company will produce up to 5 megawatts of its devices annually, but could ramp up production at the facility to 35 megawatts, according to Semprius CEO Joe Carr.

“Or we could pull the trigger and [ramp up to] 150 megawatts,” he said.

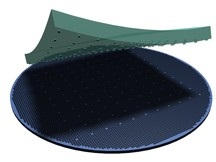

The company’s core technology promises to reduce the cost of CPV by using a unique high-efficiency photovoltaic cell printing technique called micro-transfer printing developed by the University of Illinois, according to Carr. The cells are gallium arsenide-based multi-junction cells, built onto GaAS wafers.

“We start with a Gallium Arsenide wafer and have atoms in the right spot to grow the cell on top of that,” Carr said. “In reality, once you’ve done that, it’s not used for anything. We can very easily grow those layers, between 12 and 20 layers, then we can take those layers off the substrate.”

The company then deposits the layers using a precision silicon stamp on a cheap ceramic substrate.

“That original substrate is usually two-thirds the cost of the solar cell,” Carr said. But with Semprius’ process, the GaAS wafer can be cleaned and reused to develop future cells, reducing the cost of the cells by about one-third or more.

The approach has attracted interest from electronics and manufacturing giant Siemens, which recently invested $20 million in venture capital.

“Siemens is an important deal for us,” Carr said. The company put Semprius under a lot of due diligence as part of their investment, which helped validate the technology, he said.

At this point though, the company is basically hand building all its units, according to Carr. It has about 10 kilowatts of units in the field, including a 2.5-kilowatt array with Tucson Electric and test units at the National Renewable Energy Laboratory and Sandia National Laboratory, and has been testing them for two years.

Now it’s time to start commercializing the technology.

The company attracted nearly $7.9 million in grants from North Carolina and local organizations to support the plant’s construction.

“A lot of states were interested,” Carr said. The company was courted by Florida, Ohio and Virginia, among others.

They chose to stay in North Carolina for a number of reasons. The proximity to its Durham, N.C., headquarters, skilled workforce, and the local community college system were among the reasons Carr cited. The college is across the street from the manufacturing facility’s location, and it’s agreed to develop coursework specific to Semprius and will serve as a feeding system for hires and technicians, he said.

Image courtesy of Semprius.