MIT uses virus to increase efficiency of thin-film PV

Viruses—you may hate when you get one, but these little buggers can also be incredibly beneficial. Case-in-point, new research at the Massachusetts Institute of Technology (MIT) has employed viruses to make dye-sensitized photovoltaics more efficient.

Viruses—you may hate when you get one, but these little buggers can also be incredibly beneficial. Case-in-point, new research at the Massachusetts Institute of Technology (MIT) has employed viruses to make dye-sensitized photovoltaics more efficient.

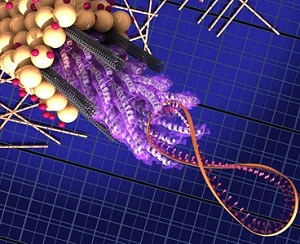

A team led by MIT’s Angela Belcher, W. M. Keck Professor of Energy, and her graduate students Xiangnan Dang and Hyunjung Yi, used a genetically engineered version of a virus called M13 to control the arrangement of semiconducting carbon nanotubes, making them more efficient in moving electrons in dye-sensitized photovoltaics.

The professor and her students were already working with dye-sensitized compounds, which is why they chose to apply the virus technique to dye-sensitized photovoltaics first, Belcher said.

The team, whose research was published online this week in the journal Nature Nanotechnology, added a water-soluble process to the manufacturing of the photovoltaics. It’s a solution-based process, already compatible with biological processing. The technique was able to raise the efficiency in the photovoltaics from 8 percent to 10.6 percent, Belcher said.

That’s not bad considering that the highest published efficiency rates for dye-sensitized photovoltaics—made by inventor Michael Grätzel—are between 11.1 percent and 11.2 percent. Plus it’s the first time the MIT lab has used the virus in producing dye-sensitized photovoltaics using commercially available materials.

“If we had people that were working with them [i.e., Grätzel’s team], we think we could get a greater improvement than what we were able to get using commercial dye,” Belcher said.

The virus does two important things, according to Belcher. It binds the nanotubes in place. Then an acidic compound is added to the liquid containing the virus and nanotubes and it grows the titanium dioxide (Ti02) compound close to the nanotubes.

“Those two sequences are right next to each other. It’s a great way of getting TiO2 and the carbon nanotubes together,” Belcher said. “You’re using the same natural mechanism to regulate charge and mimic the way biology actually works.”

The research also found that it’s important to distance the nanotubes from one another to a certain degree.

“Once you bundle too many [nanotubes], they lose efficiency. The virus is able to keep those individual nanotubes apart from each other,” Belcher said.

The diameter of the virus that does all this is 6 nanometers, according to Belcher.

“Once we grow the TiO2 around the virus and anneal them, the proteins are going to break down. Then the virus, its internal structure, will collapse,” she said.

The research team is now looking into using the nanotube structuring process for other types of thin-film photovoltaics, like those using quantum dots and organic photovoltaics.

Pictured: The M13 virus consists of a strand of DNA (the figure-8 coil on the right) attached to a bundle of proteins called peptides—the virus coat proteins (the corkscrew shapes in the center), which attach to the carbon nanotubes (gray cylinders) and hold them in place. A coating of titanium dioxide (yellow spheres) attached to dye molecules (pink spheres) surrounds the bundle. More of the viruses with their coatings are scattered across the background. Image of Matt Klug, Biomolecular Materials Group.