Cheaper Gallium Nitride could make high-performance solar more competitive

Improvements in how Bulk Gallium Nitride, a semiconductor substrate, is manufactured could bring its cost down enough for it to realistically compete with silicon in the electronics world and some in solar.

Improvements in how Bulk Gallium Nitride, a semiconductor substrate, is manufactured could bring its cost down enough for it to realistically compete with silicon in the electronics world and some in solar.

That’s what a recently released report from Lux Research found.

“Wide-band-gap semiconductor materials such as gallium nitride offer far higher performance than traditional silicon,” said researcher and report author Pallavi Madakasira.

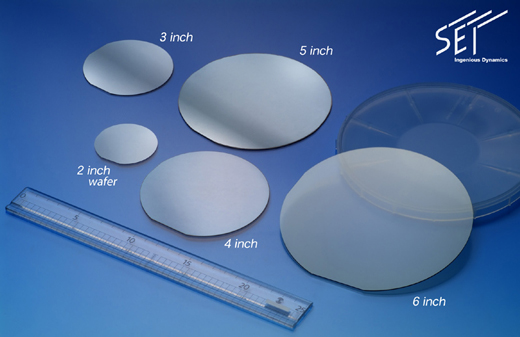

But it’s expensive – and not just a little pricey. A two-inch gallium nitride substrate costs about $2,000. That’s compared to a larger six-inch silicon substrate for $25 to $50.

“So you can see the magnitude of the price difference,” Madakasira said.

For some applications, the efficiency and performance is more important than the cost and gallium nitride makes the cut even with that price differential, she said.

It will only become more competitive as manufacturers perfect their methods and make improvements that will shrink the cost of a two-inch substrate to $730, cutting the cost in more than half by 2020.

While gallium is often used to make wafers for high-performance solar cells used primarily in space applications, this study is looking at the gallium nitride compound used in semiconductors.

There will be a place for the material in the solar industry, Madakasira said.

But the place will likely be similar to the one it occupies now – high-end solar panels where performance is more important than price.

“Solar has become especially price sensitive recently,” Madakasira said.

The higher efficiencies and greater performance offset the costs, she said. But it’s unlikely the cost of gallium nitride will come down enough to make high-end solar competitive with low-price silicon cells.

Madakasira said there are a couple methods of producing gallium nitride substrates and they’re both working on cost reduction.

While the monothermal method creates a superior product, Madakasira said the hydroid vapor phase epitaxy (HVPE) process is faster.

“I believe the HVPE method will win the war,” she said.