Cool Energy’s Stirling Engine convert waste heat to electricity

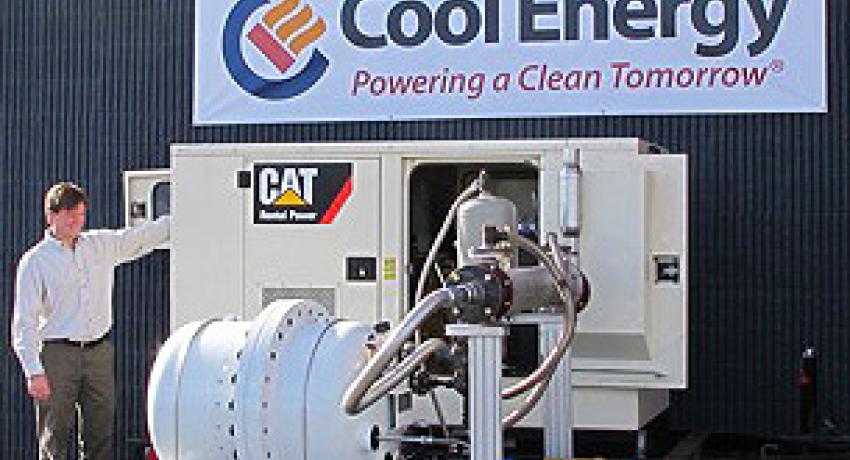

The Stirling engine has had a long and troubled past. Ever since it’s introduction in 1816 to more recent use in solar electric generating systems that just haven’t taken off. Now Boulder, Colo.’s Cool Energy, Inc. is looking at another potential use for Stirling Engines—converting waste heat into electricity. Late last month the the company was awarded a $1 million grant from the Department of Energy to help the company’s research on a 20 kilowatt waste heat Stirling engine generator.

The Stirling engine has had a long and troubled past. Ever since it’s introduction in 1816 to more recent use in solar electric generating systems that just haven’t taken off. Now Boulder, Colo.’s Cool Energy, Inc. is looking at another potential use for Stirling Engines—converting waste heat into electricity. Late last month the the company was awarded a $1 million grant from the Department of Energy to help the company’s research on a 20 kilowatt waste heat Stirling engine generator.

The Phase II Small Business Innovation Research grant will support Cool Energy’s research into building and testing its GeoHeart Engine, a 20 kilowatt Stirling engine that will generate electricity from the heat in co-produced liquids at oil and gas wells. “The recoverable heat in these liquids is currently wasted, as is the potentially valuable heat from pumps and compressors, as well as geothermal heat from non-producing wells,” the company said.

The GeoHeart Engine system will operate at temperatures between 100 degrees Celsius and 200°C, essentially at boiling temperature. “This temperature is ideally suited for the company’s low temperature waste heat recovery (WHR) system,” the company said. It’s also operating at a much lower temperature than needed to run utility steam generators or geothermal electric generators.

“Given recent advances in our designs, there is an opportunity for electricity cost savings and emissions reductions in oil and gas fields, which have significant thermal energy sources all around them,” said Sam Weaver, CEO of Cool Energy. “This is the most important increase in output capacity that Cool Energy has undertaken since beginning to develop Stirling engines for waste heat recovery six years ago.”

The electricity Cool Energy’s machine produces can be used onsite to offset a well’s power need or it can be sold to the local utility. It can also help offset some of the carbon emissions related to pumping from a well. The company also plans to study using the GeoHeart Engine with spent wells with geothermic properties to heat fluids and make emissions-free electricity with the engine.

Weaver sees a wide potential market for the device. “If widely deployed in appropriate heat recovery sectors, our power generation technology could replace up to 300 fossil fuel power plants,” Weaver said.

Referring to a National Renewable Energy Laboratory (NREL) report Cool Energy said there are about 2.5 million well bores with about 500,000 active wells. Some of which are still capable of producing temperatures that can work with Cool Energy’s technology. “Most of the wells with usable temperatures for the Cool Energy technology are in Texas, Louisiana, Mississippi, Oklahoma, Wyoming and California,” the company said. It anticipates that the market for its device could be a $500 million to $800 million market in the U.S.